- Overview

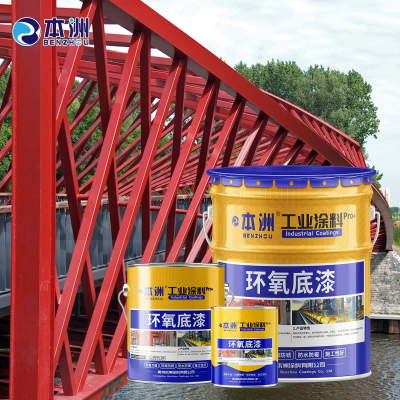

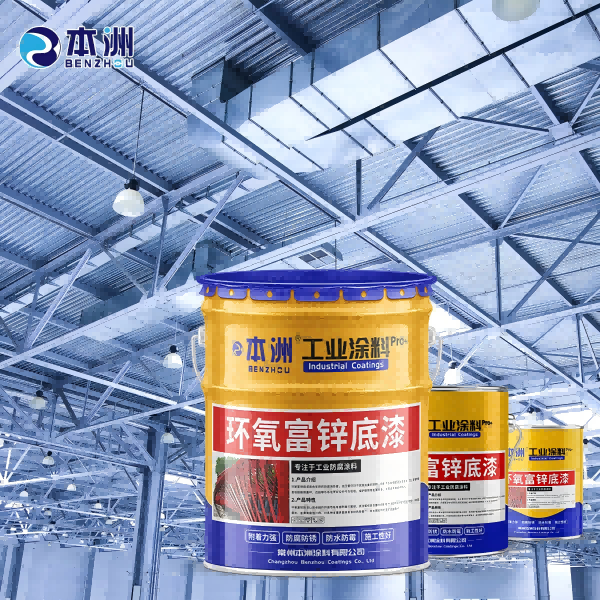

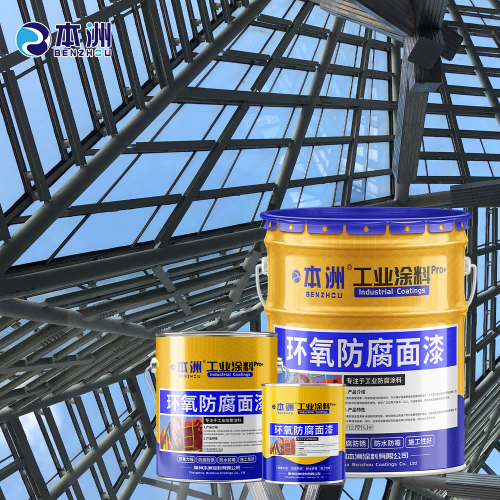

- Recommended Products

Basic parameters

Color Various colors

Ratio main agent: curing agent =20:5

Construction brush coating, spraying, rolling coating can be

Composition by resin, graphene as the main raw materials, pigments, fillers, additives, solvents and curing agent composition.

Product features

High corrosion resistance. Through its unique structural characteristics, such as large specific surface area (2630㎡/g) and two-dimensional lamel structure, graphene anticorrosive coatings can form a uniform covering layer in the paint, reducing the infiltration of moisture, ions and oxygen in the air, thus delaying the corrosion process. In addition, the maze effect of graphene can significantly improve the permeability and corrosion resistance, has a strong salt spray resistance effect, and has a life span of more than 6,000 hours.

Enhance coating densification. Graphene is able to fill in the tiny defects of the coating, reducing the coating porosity and enhancing the coating densification, which further delays or prevents corrosion factors from immersing into the substrate surface.

Electrical conductivity. Graphene has a high electrical conductivity, so it can be used to prepare conductive coatings. In conductive coatings, graphene can replace traditional conductive materials, such as metal conductors such as silver and copper, and by adding graphene to the coating, the conductive properties of the coating can be significantly improved.

Excellent corrosion resistance. It has excellent chemical inertness and can resist the erosion of many chemical substances such as acid, alkali and salt, thus protecting the substrate from corrosion and oxidation.

Chemical resistance. It can withstand most acid, alkali, chemical gas and other erosion, and has extremely high chemical resistance to a variety of chemical substances.

Excellent adhesion. The coating has a strong binding force with the matrix, and has a very strong adhesion to the surface of the steel treated by sandblasting. The coating does not fall off and the adhesion is firm.

Physical and mechanical properties. The coating is hard and wear-resistant, with good toughness and bending resistance.

Technical requirements

Product use

Suitable for a variety of substrates, including metal, concrete, wood, glass, stone, etc. It is widely used in Bridges, machinery, buried pipelines, municipal facilities, metallurgy, ships, oceans, chemicals, transformers, mines, floors, reactors, billboards, non-metal hooks and other fields, can be used for anti-corrosion coating, but also for external wall decoration.

Construction parameters

Construction structure drawing:

Supporting scheme:

Epoxy graphene zinc rich primer/epoxy zinc rich primer/inorganic zinc rich primer/cold spray zinc primer/graphene zinc powder primer/epoxy iron red primer, etc. + epoxy cloud iron intermediate paint/epoxy thick paste intermediate paint + graphene top paint

Construction notes:

The temperature of the substrate must be above the dew point of 3℃, when the temperature of the substrate is below 5℃, the paint film is not solidified, and it is not suitable for construction.

In the high temperature season construction, easy to occur dry spray, in order to avoid dry spray can be adjusted to dry spray until the diluent.

This product should be used by professional painting operators according to the product packaging or the instructions in this manual.

Steel surface:

Must thoroughly remove oil, rust, etc., to achieve the rust removal standard Sa2.5, the roughness of 30um-75um; Adopt manual rust removal method, need to reach the rust removal standard St3 level.

Concrete surface:

Concrete surface should be flat, dry, no seepage floating and water. The base that has been polluted by grease and chemicals can be washed with detergent, lye or solvent, and can also be treated by fire baking, steam blowing, etc., but it must not damage the base.

Precautions

Products should be stored in a cool and ventilated place to prevent rain, direct sunlight, avoid collision, need to isolate the fire source.

The construction site is strictly prohibited fireworks, painters should wear glasses, gloves, masks, etc., to avoid skin contact and inhalation of paint mist.

All work of coating and use of this product must be carried out in accordance with various relevant national health, safety and environmental protection regulations and standards.

If you have any questions about the use of this product, please contact our technical service department.