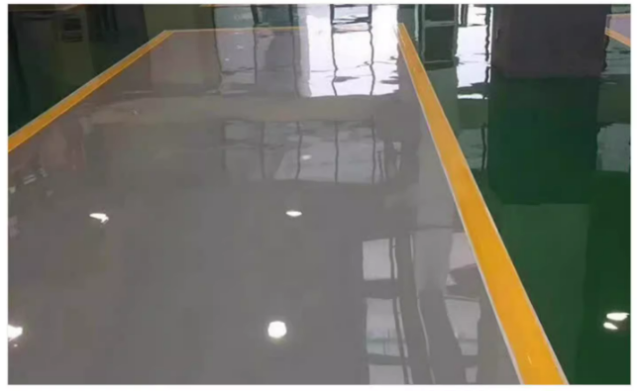

In places like parking lots, workshops, and warehouses, floors are constantly subjected to the traffic and friction of vehicles and forklifts, making wear a very serious issue. Epoxy Paint, as a commonly used floor coating material, can excellently meet this challenge, and its wear resistance is supported by various scientific principles and technical supports.

Chemical Structure Lays the Foundation for Wear Resistance

The main component of epoxy paint, epoxy resin, is the core element of its excellent wear resistance. Epoxy resin contains epoxy groups, which, after cross-linking with a curing agent, form a three-dimensional network structure of thermosetting polymers. This structure is like a tightly woven "molecular web," with chemical bonds connected between molecules, providing strong stability and rigidity.

This cross-linked structure restricts the movement of molecular chains. When subjected to friction, the molecules are not prone to sliding or breaking, thus resisting shear forces. Compared to linear polymers, the structure of cured epoxy paint is more stable, providing a solid foundation for floor wear resistance.

The Perfect Balance of Hardness and Toughness

High hardness resists wear: After curing, epoxy paint has a relatively high hardness. Hardness is an indicator of a material's ability to resist plastic deformation and surface damage. In parking lots, the pressure and friction from vehicle wheels act like tiny "chisels." Epoxy paint, with a high hardness (generally reaching 2 - 3H on the pencil hardness scale), can resist these "chisels," reducing surface scratches and wear, and maintaining the floor's integrity and aesthetics.

Good toughness absorbs impact: Epoxy paint also has good toughness, which is the ability to absorb energy and undergo plastic deformation before breaking. When vehicles and forklifts start, stop, or turn, they impact the floor. Insufficient toughness in materials can lead to cracking and accelerated wear. The toughness of epoxy paint allows it to deform like a spring to absorb impact energy, avoiding brittle fracture. This balance of hardness and toughness extends the service life of the floor.

Special Fillers Enhance Wear Resistance

To enhance wear resistance, epoxy paint often contains special wear-resistant fillers.

The role of common wear-resistant fillers: Common fillers include silicon carbide, alumina, and quartz powder. Silicon carbide, for example, has a Mohs hardness of 9.5, second only to diamond. In epoxy paint, silicon carbide particles can withstand most of the frictional forces, dispersing wear and enhancing the hardness of the coating.

The synergistic effect of fillers: Various wear-resistant fillers in epoxy paint produce a synergistic effect. Fillers of different shapes, sizes, and hardness levels work together to fill internal gaps and reduce stress concentration points. Spherical quartz powder, for example, fills gaps, making the coating structure more compact and enhancing overall wear resistance.

The construction process of epoxy paint has a significant impact on its wear resistance.

Surface preparation: Before coating, the floor must be ground and cleaned to remove oil, dust, and loose layers, increasing roughness and enhancing the adhesion of epoxy paint. Improper preparation can lead to peeling and reduced wear resistance.

Coating thickness control: The thickness of the coating affects the wear resistance of epoxy paint. Generally, within a certain range, the thicker the coating, the more wear-resistant it is. In areas with severe wear, a coating thickness of 2 - 3mm is often applied. Uniform coating thickness is also crucial, as thinner areas are more prone to wear and damage.

Construction environment requirements: The temperature and humidity of the construction environment also affect the wear resistance of epoxy paint. The ideal temperature for epoxy paint application is between 5°C and 35°C, with a relative humidity of 50% - 85%. Under suitable conditions, epoxy paint can cure better, forming a uniform and dense coating. Too low a temperature slows down or prevents complete curing, reducing performance; too high humidity can cause the coating to whiten or bubble, affecting quality and wear resistance.

Epoxy paint, with its unique chemical structure, balanced hardness and toughness, special wear-resistant fillers, and scientific construction process, demonstrates excellent wear resistance in floor applications such as parking lots, workshops, and warehouses, providing long-term and reliable protection for the floor.

Copyright © 2025 Changzhou Benzhou Coating Co., LTD. All rights reserved. Privacy policy